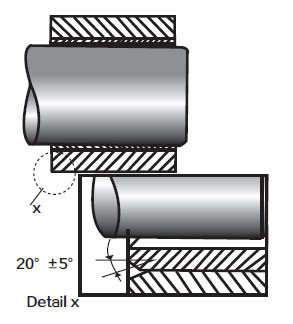

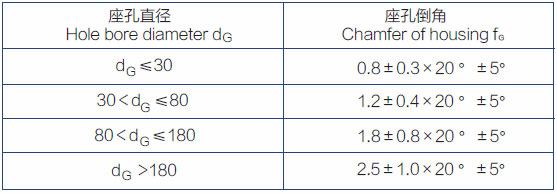

※Straight bushing

The seat holes are chamfered fGx20o±5o to make it easier for the bushing to press into the seat holes.

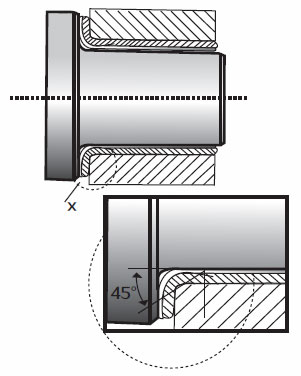

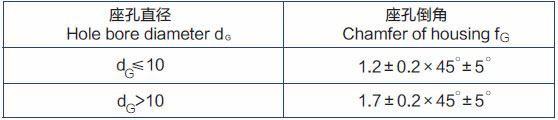

※Flanged sleeve

For the flanging sleeve, the transformation of the radius from the flanging sleeve to the axial conversion component must be considered, and the section surface must have a sufficiently large chamfer. The flanging sleeve can still support the edge of the axial load part to prevent the accumulation of dirt.

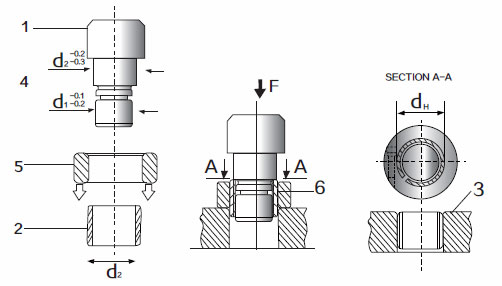

※Assembly of plain bearings and seat holes

When the sliding bearing is assembled with the seat hole, it is necessary to ensure that there is no rotation and axial movement in the seat hole of the positive bearing, and that the outer surface of the bearing and the seat hole are in full contact. Generally, the contact surface should be ensured to be greater than 85%, which is conducive to bearing the load and conducting friction heat. A lighter interference fit should be used to ensure that the bearing will not move relative to the seat hole when used. It will not make the bearing diameter interference too large resulting in the bearing inner hole deformation is conducive to assembly, bearing inner and outer surfaces should be coated with a small amount of oil or grease. Then press the bearing in evenly.

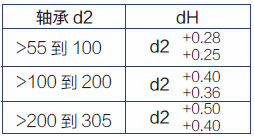

d≥55mm

1. mandrel

2. bearing

3. Seat hole

4. Side size

5. Auxiliary sleeve

6.O-ring