It is a sliding bearing made of steel plate as matrix, intermediate sintered spherical bronze powder, surface rolled polytetrafluoroethylene (PTFE) and environmentally friendly polymer material mixture. The product has the advantages of lead-free environmental protection, excellent wear resistance, high combination strength of plastic layer and copper layer, good fatigue resistance and impact resistance, etc., and has completely replaced our SF-1X, SF-1T, SF-1P, SF-1D oil-free bearings. Products after two years of testing and trial, customer response is good. It has successfully passed 1 million impact tests of CBK1 pump of Changjiang Hydraulic Parts Factory and 1 million bench tests of Shanchhuan shock Absorber Company, and the plastic layer on the surface of the shaft sleeve after the test remains intact and basically has no wear. This product is a new product created by our company, and the quality level is in a leading position in China.

| Base material: | GCr15 |

| Ultimate dynamic load; | 250N/mm2 |

| Basic hardness: | HRC≥50 |

| Friction coefficient μ: | <0.17 |

| Maximum sliding speed: | 0.17m/s |

| Maximum service temperature: | -100~+300 |

| Service limit PV value: | 2.5N/mm2.m/s |

Industry application:

For example: winding machine support, crane support, but not suitable for use in water or acid and alkali occasions.

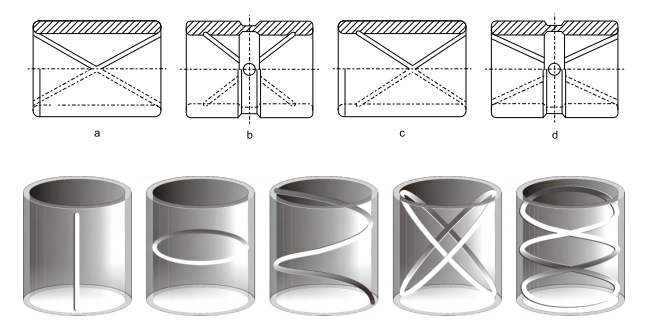

The oil tank forms are: