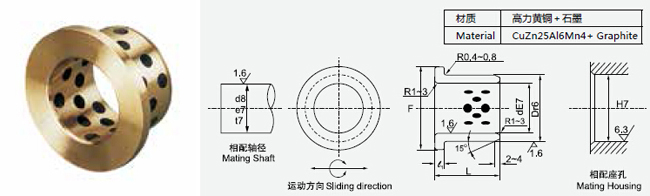

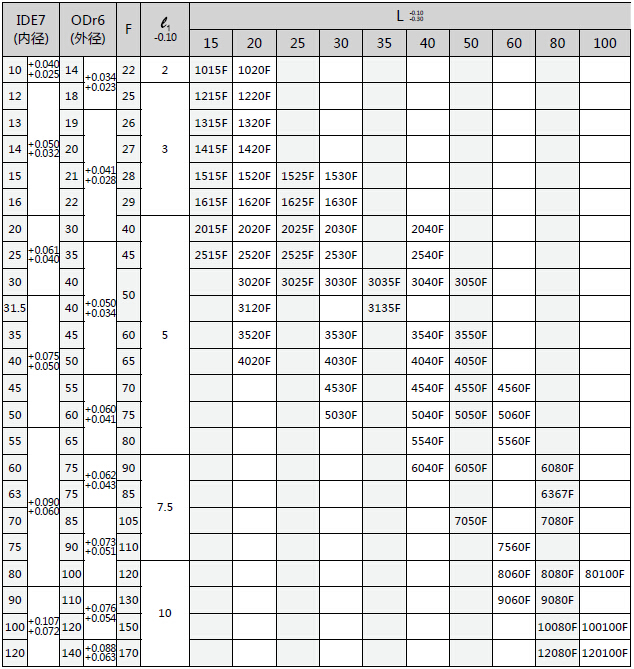

RCB - 650 with high strength copper alloy (CuZn25Al5 CuZn24Al6Fe3Mn4, SAE430B, HBsC4) as basic material, According to the operating conditions, the holes are machined in a certain proportion of the working face and filled with a solid lubricant. The high-strength copper alloy provides a high bearing capacity while the solid lubricant can form a low friction pair. Under dry friction conditions, we design a pre-lubricated film on the bearing surface to ensure that the solid lubricant is transferred to the dual parts in the shortest possible time and an effective solid lubricant film is formed.